When used with domestic wastewater, MBR processes can produce effluent of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages of MBRs over conventional processes include small footprint, easy retrofit and upgrade of old wastewater treatment plants. It is possible to operate MBR processes at higher mixed liquor suspended solids (MLSS) concentrations compared to conventional settlement separation systems, thus reducing the reactor volume to achieve the same loading rate.

Recent technical innovation and significant membrane cost reduction have enabled MBRs to become an established process option to treat wastewaters. As a result, the MBR process has now become an attractive option for the treatment and reuse of industrial and municipal wastewaters, as evidenced by their constantly rising numbers and capacity.

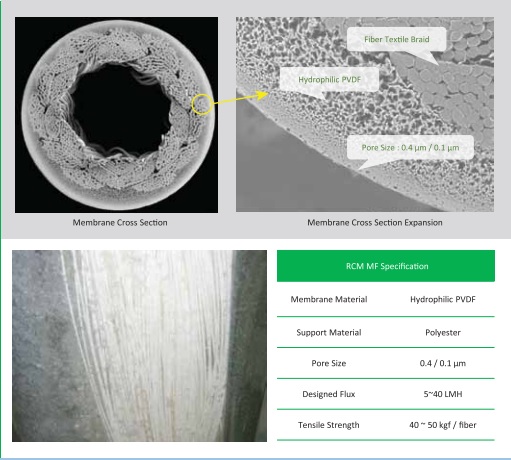

Geed offers Hydrophilic modified PVDF (Polyvinylidene fluoride) composite membrane, called as RCM (reinforced capillary membrane), which can be applicable to MBR (Membrane Bio-reactor) process. Geed manufactures Hi-flux RCM membranes for MBR process. Generally it is offered as the package systems for MBR process. In addition, RCM is applied to using MF membrane for waste water treatment and UF membrane for pretreatment of RO membrane.